Cagiva mito 125 for sale here on Ebay UK

etc )

Rare to find the 35 tm's now try on ebay uk here

Free Carb Manuals

dellorto carb manual

Cagiva Mito 125 Dellorto 28mm for sale now on

|

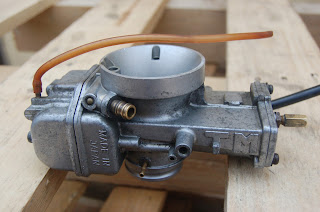

| Mikuni carb tm35mm |

Rare to find the 35 tm's now try on ebay uk here

Free Carb Manuals

dellorto carb manual

mikuni carb manual

Download the manual, read it. Stripping and cleaning carb is one of the easiest jobs to do on a 2stroke bike.

Meccano is harder to get to grips with than stripping and cleaning a carb. Don't let it scare you - it really is easy to do... otherwise, I'd suggest selling the bike and getting a 4T, as any regular maintenance that is a necessity for a 2stroke bike is gonna scare you, and you're gonna end up forking out hundreds in labour hours to the local bike shop for tasks that really you should learn to do yourself.

Grey residue is likely result of water mixed with 2T oil saturating / flooding your spark plug as you have water in the float chamber that is submerging the main jet (main jet is in base of float bowl, and petrol floats on water), so when you open throttle, bike gets a lung full of water rather than fuel.

Flip up tank. Turn fuel off. Look down at carb. Either side of it you'll see 2x jubilee clips clamped over rubbers. Undo those. Grab carb... move it backwards and forwards and work it out from between the rubbers. Keeping it the right way up, undo big brass bolt in bottom. Bottom will then come off. This bottom part is the float bowl. Ideally, open the bolt over a glass bowl so that you catch the spilt fuel and can inspect it for signs of water or contamination.

If no signs of globules of liquid suspended in fuel, inspect the bottom of the carb that you removed for signs of contamination - dust, rust, dirt etc. Rinse it out.

The jets are small brass things with a hole in the middle and a flat-blade screwdriver cut - you'll see em. Take them out one at a time, blow thru them, rinse in boiling water. Put em back in again. Tighten em til they nip gently.

Put float bowl back on. Do up the big bolt to secure it in place. (Note, this big bolt has the main jet fitted in the opposite end of it).

Fit carb back in between the rubbers. Put the jubilee clips back on. Turn on fuel tap.

See if it starts. See if problem still exists.

Cagiva Mito Evo Carb Tuning Kit click here to read more about this on Ebay UK.

Cagiva Mito Evo Carb Tuning Kit click here to read more about this on Ebay UK.

CARB SETUP

Set it to rev at 2000 with the idle screw, then twiddle the air screw just to the left of the idle screw... turn it all the way in, then back out 1.5 to 2.5 turns, listening to engine. As you turn it, revs should increase slightly. Set it to a point that revs are at highest and smoothest. Now use the idle screw to tune it back down to around 1100rpm ( i normally set mine at 1500rpm )... that should be the carb as set as it can be.

in = increase

-----------------------------------------------------------------------------------

Type ....................... Dell'Orto PHBH 28 BD

Venturi Diameter ..............................mm 28

High Speed Jet . .................................. 100

Starter Jet . ............................................ 65

Low Speed Jet . ..................................... 55

Emulsifier ............................................... 55

Throttle Piston ............................... 44.59.00

Metering Pin . ........................................ X 4

Metering Pin position . ........................... 3rd

Main Nozzle . ................................. 270 BN

Float .................................................. g 9,5

Idle Mixture Adjusting Screw . ...... 1 and 1/2

Type ....................... Dell'Orto PHBH 28 BD

Venturi Diameter ..............................mm 28

High Speed Jet . .................................. 110

Starter Jet . ............................................ 65

Low Speed Jet . ..................................... 65

Emulsifier ............................................... B65

Throttle Piston ......................................... .45

Metering Pin . ........................................ X 4

Metering Pin position . ........................... 3rd

Main Nozzle . ................................. 270 BN

Float .................................................. g 9,5

Idle Mixture Adjusting Screw . .......... 1

Type ....................... Dell'Orto PHBH 28 BD (A-CH)

Venturi Diameter ..............................mm 28

High Speed Jet . .................................. 120

Starter Jet . ............................................ 65

Low Speed Jet . ..................................... 38

Power Jet............................................... 90

Low Emulsifier.......................................BF 1

Throttle Piston ...................................... .50

Metering Pin . ........................................ X 58

Metering Pin slot . ................................. 1st

Main Nozzle . ................................. 266 DU1

Float .................................................. g 9,5

Idle Mixture Adjusting Screw (turns). ...... 1/2

REGULATION OF IDLE

This regulation must always be

carried out with warm engine

and throttle closed.

Operate as follows:

- remove the right or left-side

fairing according to

instructions on page 14;

- tighten adjusting screw (1) of

the fuel valve to obtain a high

speed rate (2,000 RPM; by

turning clockwise, the speed

increases, by reversing the

operation it decreases);

- tighten or loosen screw (2)

that adjusts mixture dosage

until getting regular engine

rotation;

- progressively loosen gas

valve adjusting screw (1) until

reaching 1,000 RPM.

- reassemble the side fairing.

At high speed fuel mixture

dosage is automatic, and

cannot be opened from the

outside. Should the engine run

irregularly, clean the carburetor.

=================================================================

Rare to find the 35 tm's now try on Ebay uk here

Type ....................... Dell'Orto PHBH 28 BD

Venturi Diameter ..............................mm 28

High Speed Jet . .................................. 100

Starter Jet . ............................................ 65

Low Speed Jet . ..................................... 55

Emulsifier ............................................... 55

Throttle Piston ............................... 44.59.00

Metering Pin . ........................................ X 4

Metering Pin position . ........................... 3rd

Main Nozzle . ................................. 270 BN

Float .................................................. g 9,5

Idle Mixture Adjusting Screw . ...... 1 and 1/2

Type ....................... Dell'Orto PHBH 28 BD

Venturi Diameter ..............................mm 28

High Speed Jet . .................................. 110

Starter Jet . ............................................ 65

Low Speed Jet . ..................................... 65

Emulsifier ............................................... B65

Throttle Piston ......................................... .45

Metering Pin . ........................................ X 4

Metering Pin position . ........................... 3rd

Main Nozzle . ................................. 270 BN

Float .................................................. g 9,5

Idle Mixture Adjusting Screw . .......... 1

Type ....................... Dell'Orto PHBH 28 BD (A-CH)

Venturi Diameter ..............................mm 28

High Speed Jet . .................................. 120

Starter Jet . ............................................ 65

Low Speed Jet . ..................................... 38

Power Jet............................................... 90

Low Emulsifier.......................................BF 1

Throttle Piston ...................................... .50

Metering Pin . ........................................ X 58

Metering Pin slot . ................................. 1st

Main Nozzle . ................................. 266 DU1

Float .................................................. g 9,5

Idle Mixture Adjusting Screw (turns). ...... 1/2

REGULATION OF IDLE

This regulation must always be

carried out with warm engine

and throttle closed.

Operate as follows:

- remove the right or left-side

fairing according to

instructions on page 14;

- tighten adjusting screw (1) of

the fuel valve to obtain a high

speed rate (2,000 RPM; by

turning clockwise, the speed

increases, by reversing the

operation it decreases);

- tighten or loosen screw (2)

that adjusts mixture dosage

until getting regular engine

rotation;

- progressively loosen gas

valve adjusting screw (1) until

reaching 1,000 RPM.

- reassemble the side fairing.

At high speed fuel mixture

dosage is automatic, and

cannot be opened from the

outside. Should the engine run

irregularly, clean the carburetor.

=================================================================

|

| TM35mm carb Cagiva mito |

Rare to find the 35 tm's now try on Ebay uk here

mito evo racing '95 original settings mikuni tm35:

throttle slide 5.5

jet-needle 6AEL4-60, 4th clip from below, 2th from top

pilot jet 45

main jet 310

air screw 1.5 turns from closed

mikuni tm35-1 'aftermarket' setting:

throttle slide 6.0

jet-needle 6EN11-53, 3th clip

pilot jet 20

main jet 350

Cagiva mito 125 carb strip down videos ?

Mikuni tuning guide

Mikuni performance guide

see more cagiva mito 125 posts here

You could just dump it all in your ultrasonic cleaner , get one they are excellent

try Ebay uk here or Amazon uk here

see more cagiva mito 125 posts here

No comments:

Post a Comment

No spam